What characterizes us in all production procedures is to have the process under control, parameterized, according to parameter tolerances, real time control of parameters, and actions in the productive process. This data remains registered for each production job.

We are developing ALCION towards the industry 4.0 as a model of production and management, to enable us to anticipate any outcome, from design to deviations of each parameter.

PRODUCTION RESOURCES

- Cell injection, 100% automated and controlled by a process control system, between 700 Tn. and 1300 Tn.

- Machining centers, with control parameters, 100% robot operated and quality controlled by artificial vision.

- Transfer machines, 100% robot operated, and with control parameter.

- Automatic lathes.

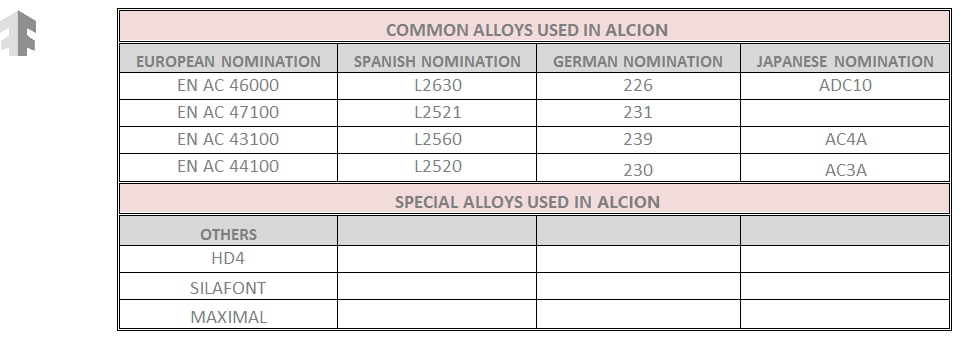

Alloys

ALCION has high flexibility for using different alloys at the same time in the die casting cells.

- The most used alloys in ALCION are listed below:

CASTS AND DEVICES

From Production Engineering, the Cast Project Management guarantees the follow-up in all the phases of the cast project, both in the quality demand and the fulfilment of all the pacification stages with the objective to meet the delivery terms and guarantee the life span of the devices.

We select steel with the best characteristics for the cast fabrication.

Device development: We count with the most used informatics design programs for parts, casts, cutting, mechanization devices, control devices, in the sector.

Client area

Client area